- info@qtsndt.com

- +1 908-925-5120

- Mon - Sat : 7:00 - 4:00

Our Services

Services

Magnetic Particle (MT)

MT is a process that uses both wet fluorescent or dry particles for detecting surface and shallow subsurface discontinuities in ferromagnetic materials. Imperfections distort the magnetic field and concentrate the iron particles near imperections.

Liquid Penetrant (PT)

Liquid penetrant examination methods are utilized to detect open, surface cracks, or defects in materials. Red dye or fluorescent penetrants are utilized as well as various types of developers.

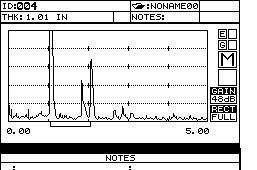

Ultrasonic Thickness (UT)

Ultrasonic examinations are performed for corrosion monitoring and the detection and sizing of internal defects, flaws or discontinuities in piping, tanks, welds or other components. Ultrasonic sound waves are introduced into the test object, any imperfections reflect the wave and is detected by the reciever.

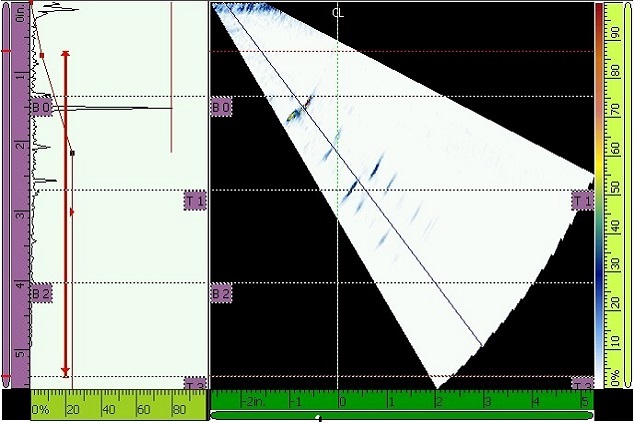

Phased Array (PAUT)

Phased Array Ultrasonic Testing is an advanced technique that uses an ultrasonic testing probes made up of numerous small elements. PAUT is ideal finding flaws in welds, cracks, voids and pits caused by corrosion and other damage mechanisms.

Contact Point Inspection

Contact point inspection is an ultrasonic testing method that utilizes CHIME waves. This allows for estimating metal loss at normally inaccessible areas, such as hangers and contact points, by using the attenuation drop method.

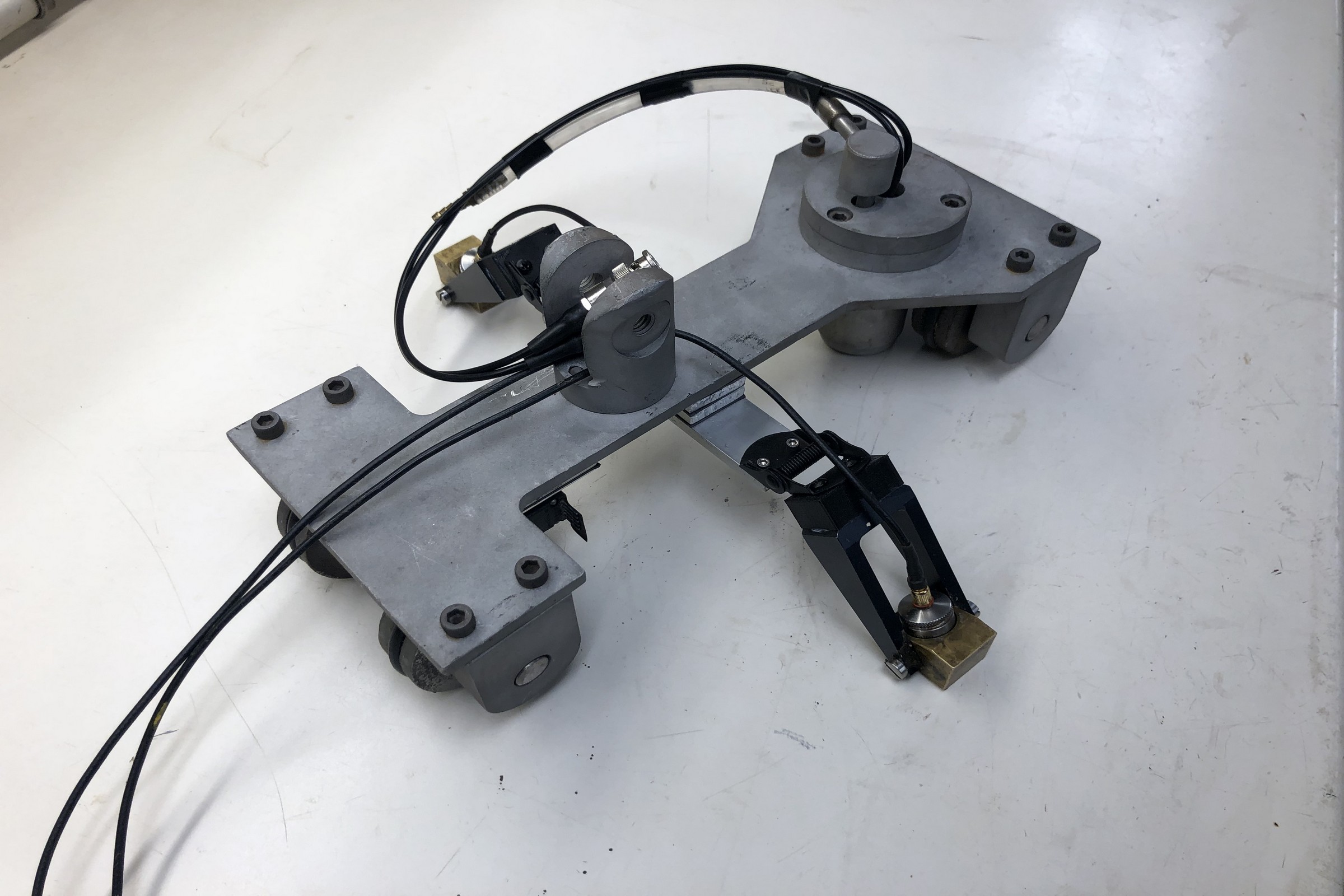

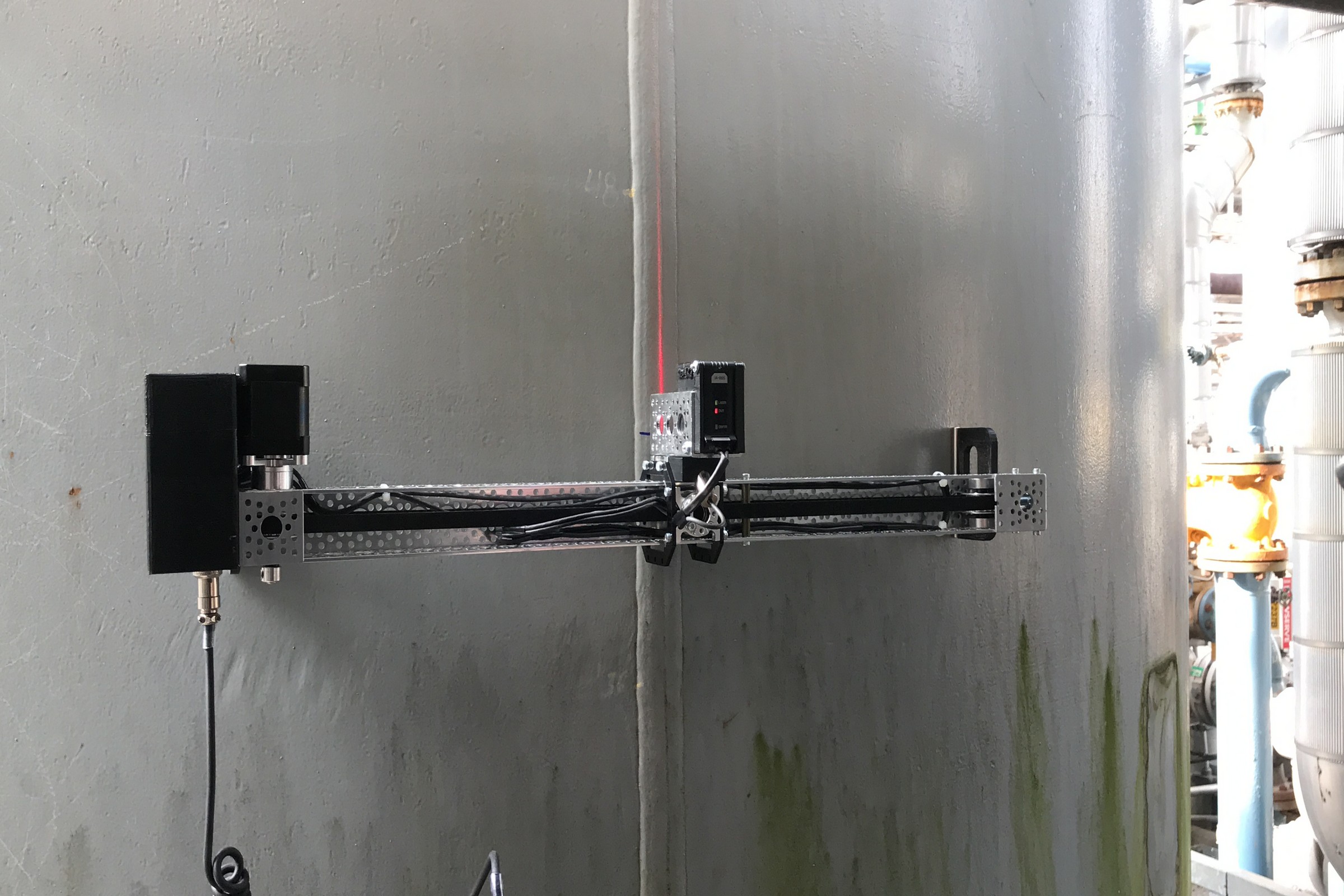

Automated UT (AUT)

Automated ultrasonic testing uses mechanized means to drive the ultrasonic scanning equipment around the part being tested. This allows for a more timely and more repeatable way to monitor larger areas for mechanical integrity.

Positive Material Identification (PMI)

Positive Material Identification is a fast and non-destructive testing method for verifying the chemical composition of metals and alloys.

Tank Floor Scanning (MFL)

Scanners utilizing magnetic flux leakage are used to examine tank floors and provide detailed mapping of top side and under side corrosion.

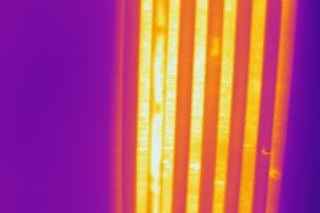

Thermography (IR)

Infrared radiation is emitted by all objects based on their temperatures. An infrared imager is used to measure this energy without contact for a number of different applications including fired heaters, refractory lined equipment, electrical equipment and much more.

Laser Profilometry (LP)

Laser Profilometry is a non-contact technique used to scan and map the surface of an object. Laser profilometry is used for a number of applications including surface corrosion mapping and shell displacement surveys.

Hardness Testing

The application of hardness testing enables you to evaluate a material's properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require.

Tracer Gas Testing

Tracer gas testing is a method used to detect gas leaks. Tracer gases, such as helium, are used to fill a volume with positive pressure to displace oxygen. A sniffer probe is then used to detect leakage, which would indicate a crack in a weld or a plate.

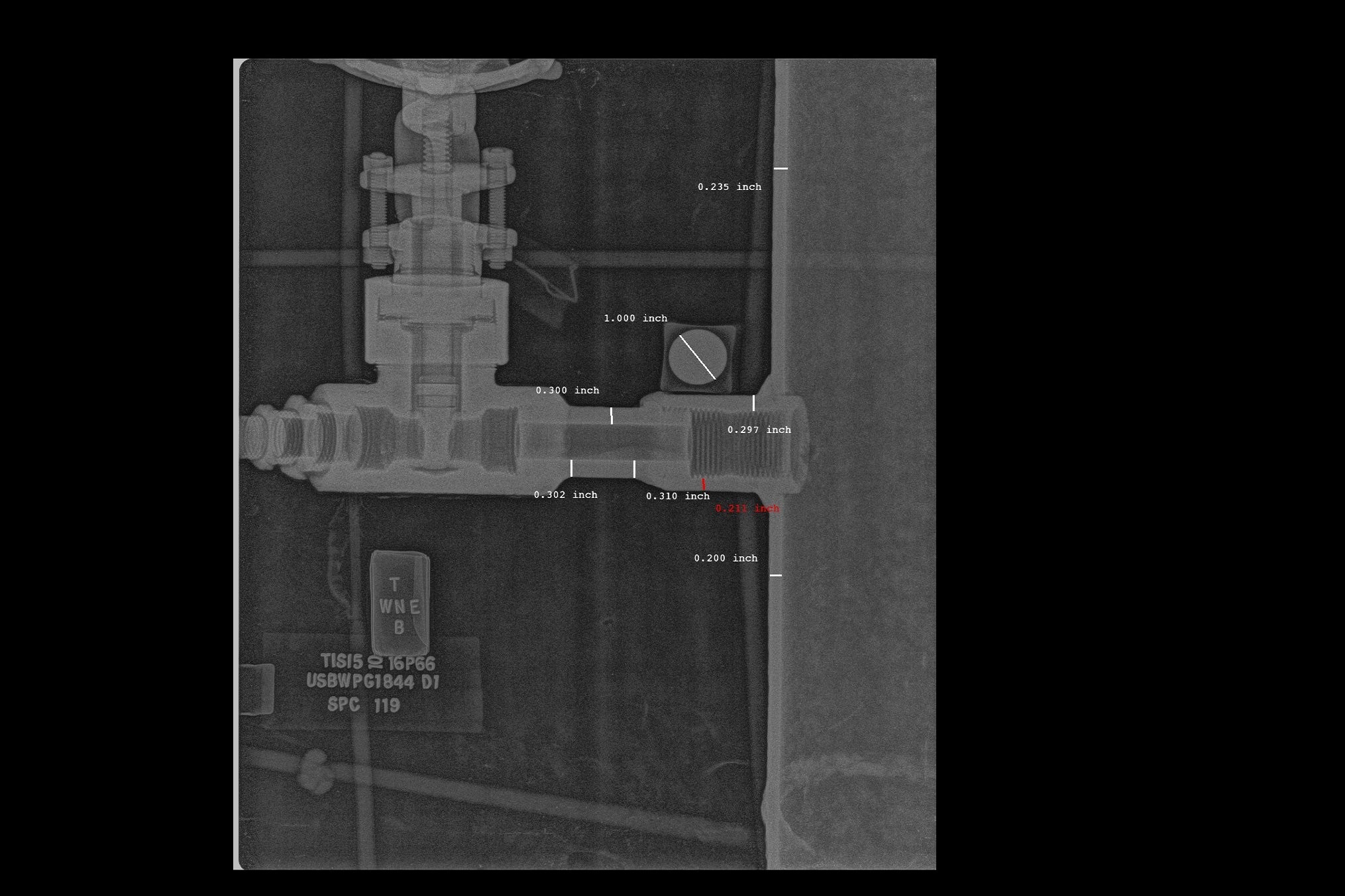

Radiography (RT)

Radiography is an imaging technique using X-rays to view the internal form of an object. This extremely popular technique is able to detect a wide range of defects in multiple materials and is able to produce a permanent record of each inspection.

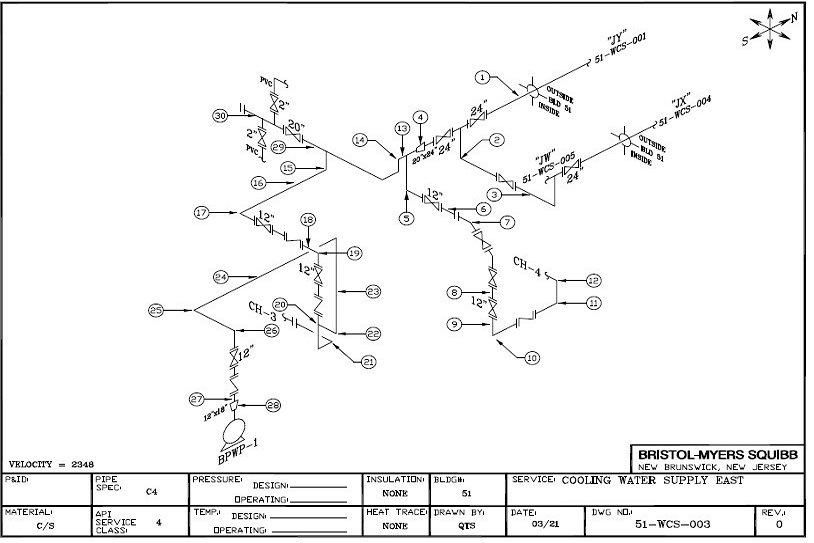

CAD

QTS can assist our customers with all their documenting and drafting needs including creation of isometric drawings and large scale printing.

API Inspections

QTS can provide API certified inspectors. API-570 Piping Inspection, API-510 Pressure Vessel Inspection, API-653 Tank Inspection, API-581 Risk-Based Inspection.